Battery test equipment

Topsizer Plus Laser Particle Size Analyzer

Topsizer Plus Laser Particle Size Analyzer

——A Peak of Particle Size Detection & Analysis Technology in China

Topsizer plus is another high-end laser particle size analyzer launched by Zhuhai Omec Instruments Co., Ltd. as a wholly-owned subsidiary of Malvern Panalytical after TopSizer, which is widely praised. Topsizer Plus has introduced advanced optical design in the world, combined with the technical accumulation of Omec in the past 30 years, and has adopted the global supply chain system, the measurement range of laser diffraction method can reach 0.01-3600μm, which represents the highest technology level of domestic laser particle size analyzer. Topsizer Plus maintains the advantages of TopSizer, such as wide range, good repeatability, high resolution, strong real test performance and high intelligence, by further improving optical design, hardware and inversion algorithm, Topsizer Plus expands its test scope and actual test performance, it can be widely used in various fields of modern industry such as chemical industry, machinery, building materials, energy, pharmaceuticals and so on.

In many industries, such as lithium-ion battery, pharmaceuticals, hydrology and fine chemicals, many users choose Omec laser particle size analyzers, especially TopSizer, in addition to the trust for Omec brand and technology, but also because it comes from the product technology and quality management system of Malvern Panalytical, the instrument test results have excellent accuracy, authenticity and sensitivity.

Topsizer series products ensure that the test results and analysis capabilities are consistent with the gold standards of domestic & foreign and upstream & downstream industries, whether it is raw materials, preparations or positive and negative materials for lithium ion batteries. This not only saves the time and cost of method development and method transfer for users, but also avoids the economic losses and risks caused by inaccurate particle size detection. Whether in R&D, process control or quality control, it can bring real value to users.

Technical instruction:

1. Measure rang: 0.01-3600μm(wet, depends on sample), 0.1~3600μm (dry, depends on sample)

2. Theory: Mie theory

3. Repeatability error: ≤0.5%(standard particle D50)

4. Accuracy error: ≤±0.6% (standard particle D50)

5. Test speed: within 10 seconds for common sample

6. Sampling way:

Automated wet-dispersion test*, the sample feeder adopts a high-power precision centrifugal pump with an imported motor, the stirring speed can reach 4000 rpm, built-in ultrasound is continuously adjustable (with SCF-105B).

Automated dry-dispersion test*, dispersed working pressure of sample feeder is 0.05-0.6 MPa, stepless continuous adjustment. Vibration sampling of piezoelectric ceramics crystal can be continuously adjusted at a speed of 0-100% (with DPF-110).

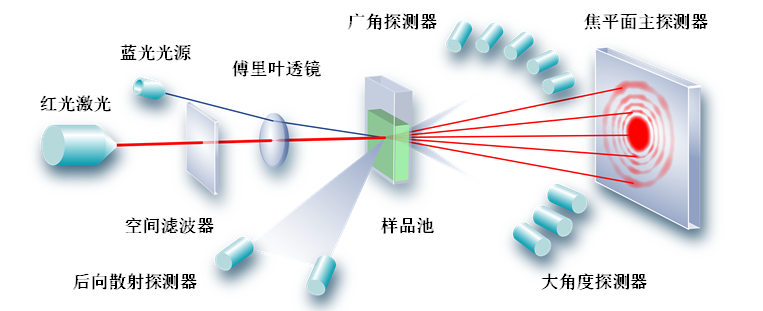

7. Light path system:

The dual light source design uses imported He-Ne laser with a wavelength of 0.6328μm and a semiconductor blue light source with a wavelength of 0.466μm, which greatly improves the resolution of nanoparticles and a small number of large particles. Laser power is stable all the time, power fluctuation is less than 0.5%;

The instrument design conforms to the international laser safety standards and has the function of laser beam automatic protection.

It adopts an integrated high precision all-aluminum alloy optical platform, which is stable and reliable for a long time.

Single lens design, using lens Back-Fourier transform structure; the optical system is completely closed to effectively solve the problem of dust pollution;

Detector can realize automatic alignment.

8. Detector:

There are 103 detecting channels. The three-dimensional detection system consists of forward, lateral, large angle and backward photodetectors. The maximum detection angle is 140°, the minimum detection angle is 0.016 °, no blind area.

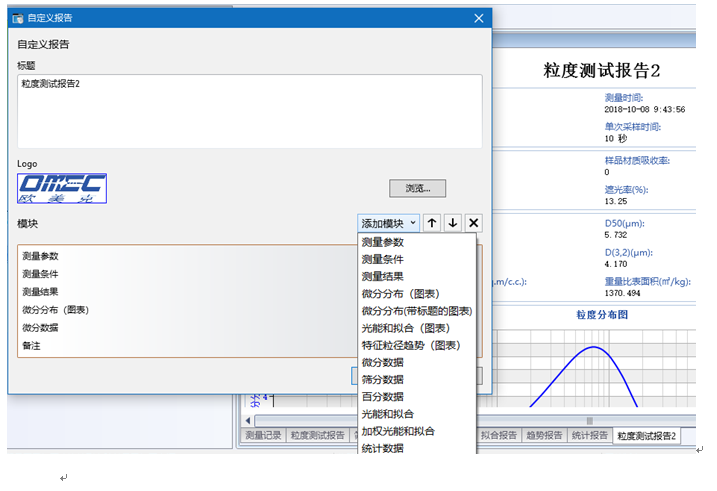

9. Software function:

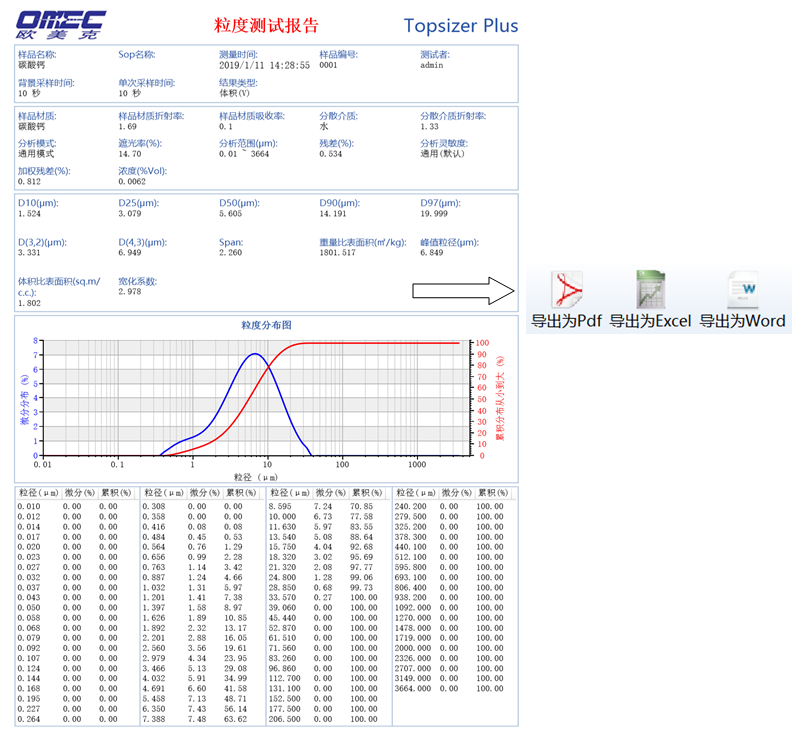

Rich customized report function, convenient for users to obtain data and define report style flexibly;

Software design modularization, invisible instrument status, humanized operation interface.

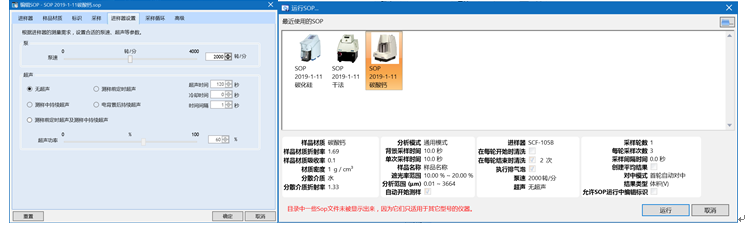

SOP standardization operating procedure

Various data analysis models are used to meet the testing needs of samples with different characteristics.

Clear navigation function and flow interface

With artificial intelligence, the instrument has the function of self-inspection, automatic identification of the feeding system;

The electric background can be automatically measured before each measurement, which can effectively eliminate the influence of electrical noise on the test results.

Various ways of measuring data export to facilitate data exchange;

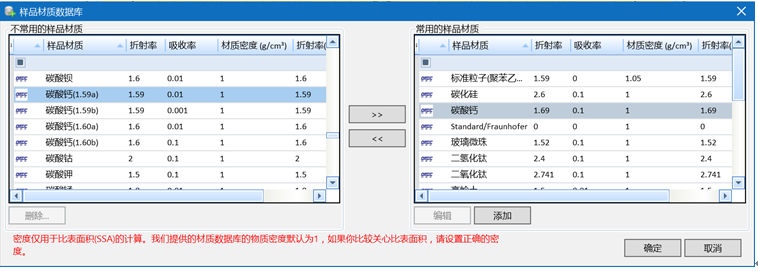

Perfect and open database of sample characteristic parameters with common refractive indexes and absorptivity parameters

Volume distribution, surface area distribution, length distribution and quantity distribution can be converted to each other.

Provide software solutions that meet the requirements of GMP Annex "Computerized System", with user classification, authority management, data integrity and traceability functions.

10. Dimension;

Mainframe:1330×266×380 mm

Circulated sample feeding system: 265×325×405mm(SCF-108),210×260×345mm(SCF-105B)

Dry-dispersion sample feeding system: 305×245×295mm(DPF-110)

1. Application

Measure the particle size distribution of samples. It can measure not only the sample dispersed in liquid, but also the powder materials dispersed in gas.

2. Theory:

Light is an electromagnetic wave. When light meets with particles on it way of traveling, the interaction between light and particles will result in deviations of part of the light, which is called light scattering. The bigger the scattering angle is, the particle size will be smaller, the smaller the scattering angle is, the particle size will be bigger. The laser diffraction particle size analyzer will analyze the particle distribution according to this physical character of the light wave.

3. Advanced light system

Double light resource technology

Topsizer Plus adopts double light resource design, red light is imported He-Ne laser with 0.6328μm wavelength, and solid blue auxiliary laser with 0.466μm wavelength,it improves the resolution ratio of the instrument for nanometer particles and few large particles. In the domestic mainstream laser particle size analyzers, red and blue dual-color light source technology is exclusively adopted by Omec.

Imported high-performance He-Ne laser & power supply, stable and reliable optical quality

With the imported famous brand He-Ne laser with long life, low noise and high stability and the matching

laser power supply, it can provide instrument with nearly perfect optical quality. On the basis of stable wavelength brought by gas laser itself, Topsizer Plus light source system has the characteristics of stable power, short preheating time, high and stable polarization ratio and high waveform purity. It ensures that the instrument can work stably in different working environments and has the performance of lasting accuracy without user calibration.

Folding light path design

The light path of the Topsizer Plus adopts the closed linear light path design, there is no stray light caused by superfluous reflective optical components, and no dust pollution interference. At the same time, a high-precision all-aluminum alloy optical platform is adopted to ensure that the optical path is stable and reliable.

Back-Fourier transform single lens design

Single lens design, adopt the structure of lens back Fourier change, which breaks through the constraints of the pupil of the Fourier lens, and can receive accurate scattered light signals from all spatial angles of the front and back of the window. The single lens optical path design reduces the refractive and reflective surfaces to a minimum, which can further reduce the background noise to a very low level and improve the signal-to-noise ratio of the instrument.

Long-focus Fourier lens

Topsizer Plus adopts Fourier lens with long focal length. By increasing the distance between the measuring window and the photodetector plane, the photodetector can accurately distinguish the scattered light signal of smaller angle, greatly enhance the testing ability of large particles. The upper limit of the instrument is 3600μm.

Imported photodetector with reasonable distribution and high sensitivity

Topsizer Plus adopts the specially customized imported photodetector to ensure that the instrument has high resolution and sensitivity. There are 103 detection channels. The three-dimensional detection system consists of forward, lateral, large angle and backward photodetectors. The maximum detection angle is greater than 140° and the minimum detection angle is 0.016°. Combining with the blue light scattering signal, the seamless reception of the scattered light signal in all angle range is realized completely and accurately.

Intelligent automatic alignment

Automatic alignment can be completed in tens of seconds, either as part of the automatic measurement or by clicking the mouse on the screen. The optical alignment accuracy of intelligent automatic alignment system ensures the repeatability of multiple measurements.

Excellent dispersing system

Wet dispersion: standard configuration SCF-108 sample feeding system, adopt the advanced circulation loop design and high-power precise centrifugal pump, the stirring speed can reach 4000 rpm, with the advantages of efficient dispersion, cleaning and draining ability. The inserted inside ultrasonic can reach 100W, which contains 1000ML sample cell, customers can replace it to other volume according to their need. SCF-105B fully automatic circulating sample feeding system can be selected, all test operation can be automatically controlled except for adding samples. The sampling cell is made of 316L stainless steel, equipped with a precision mixing device with a high efficiency of 50W bottom ultrasonic and a speed of 4000 rpm, all of which can be continuously adjusted.

Dry dispersion: standard configuration DPF-110 automatic dry-dispersion sample feeding system with stepless adjustable, dispersion pressure of 0.05-0.6 MPa and triple adjustable cutting mechanism is designed to meet the requirements of various sample measurement for dispersion strength. Built-in pressure sensor and negative pressure sensor, measurement window is fully closed, with negative pressure protection device, can effectively prevent window and mainframe pollution.

4. Powerful analysis software Rich customized report function, convenient for users to flexibly obtain data and customize report

Users can flexibly define the title and logo of the report, select the modules displayed in the report, and set these modules, can adjust the number of rows, columns and coordinate axis range, report content and parameters can be set as required.

Software design modularization, invisible instrument state, humanized operation interface.

Clear navigation function and flow interface

The instrument has intelligent and automatic operation. It can self-check and automatically identify the sample feeding system, automatically measure the background before each measurement, effectively eliminate the influence of electrical noise on the test results. Automated sample feeder can be equipped for automatic dry & wet particle size measurement, manual sampling also has clear navigation testing function.

SOP standardization operating procedure, eliminate the influence of human factors, standardize analysis and testing process

SOP measurement program editing and running:

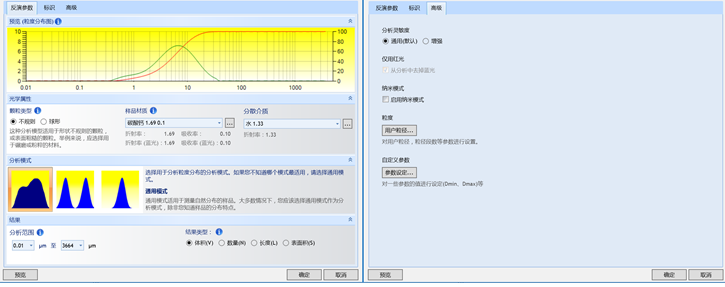

Multiple data analysis models, to meet the test requirements of samples with different characteristics

Volume distribution, surface area distribution, length distribution and quantity distribution can be converted to each other. The specified particle size segment can be set according to the user's needs.

Perfect and open database of sample characteristic parameters with common refractive index and absorptivity parameters

Various ways of measuring data export to facilitate data exchange

![]()

Provide software solutions that meet the requirements of GMP Annex Computerized System, compatible with the requirements of CFDA/FDA cGMP 21CFR for user classification, authority management, data integrity and traceability

5. Distinguished instrument performance

An important feature of Topsizer Plus’s upgrade from TopSizer is that it retains complete consistency with the data between 0.02-2000μm in TopSizer. The measurement range is further improved to 0.01-3600μm by upgrading the optical path, hardware and algorithm.

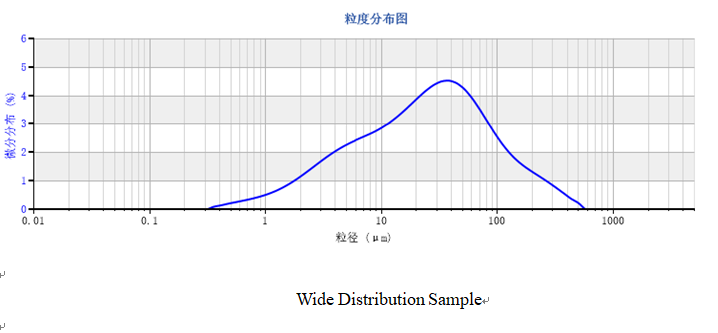

Wide measurement range

Different from other solutions on the market that use different technologies through splicing to improve test range, Topsizer Plus has a real measurement range of 0.01-3600μm. It uses static light scattering technology to detect sub-micron to millimeter-sized particles, which meets the national standard of GBT19077-2016 particle size analysis laser diffraction method, it can also meet all kinds of requirements for particle size measurement and control in different powder industries

.

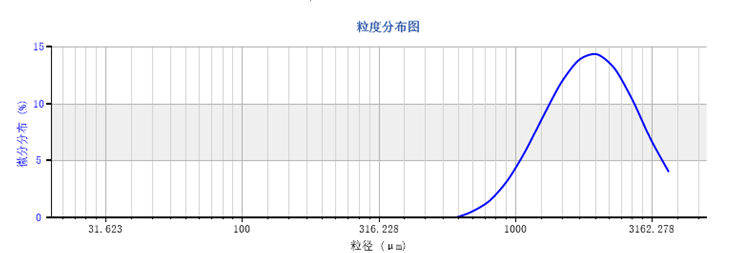

Perfect test performance for large particles

7-14 mesh standard particle

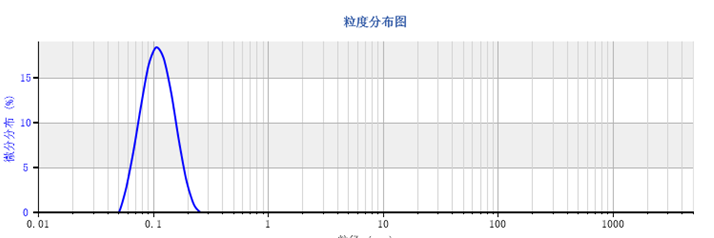

Good recognition capability for nanometer and submicron particles

100nm latex

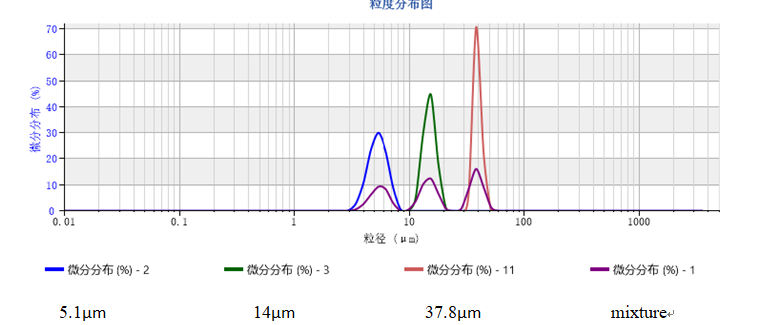

Excellent resolution

Topsizer Plus can accurately measure the small changes of particle distribution in samples, accurately reflect the actual particle size distribution of samples, and fully meet the needs of technical research and quality control. The mixture sample in the figure is 5.1μm /14μm /37.8μm in proportion.

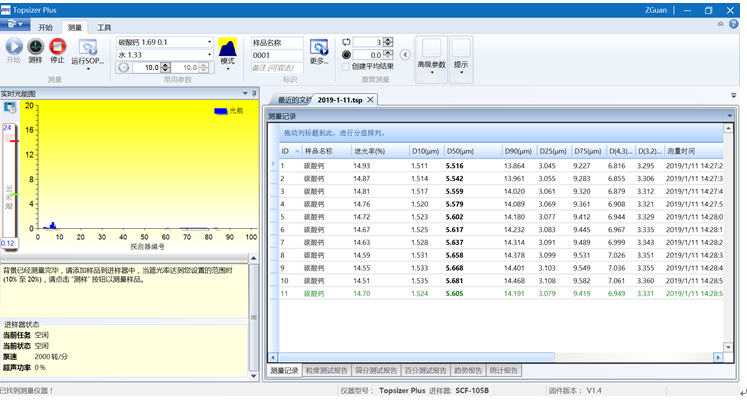

Good repeatability

Topsizer Plus uses automatic laser calibration system and automatic alignment system, which ensures the accuracy of laser angle calibration, avoids the drift of optical path and ensures that the repeatability error of the test is less than 0.5% (standard particle D50).

Sampling/time | D10/μm | D50/μm | D90/μm |

1 | 3.848 | 4.995 | 6.322 |

2 | 3.845 | 4.995 | 6.328 |

3 | 3.834 | 4.986 | 6.319 |

Average | 3.842 | 4.992 | 6.323 |

SD | 0.007 | 0.005 | 0.005 |

RSD (%) | 0.19 | 0.09 | 0.08 |

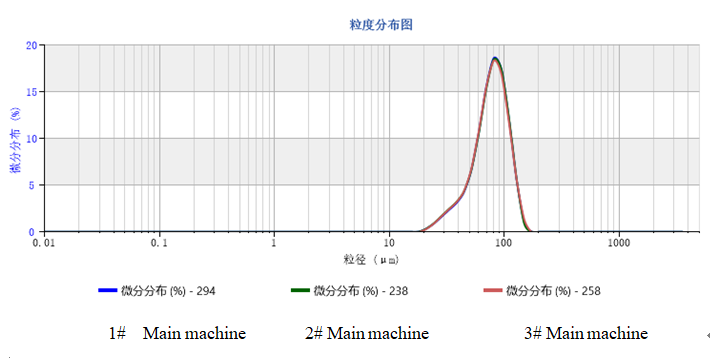

Excellent reproducibility

Be capable of good reproducibility among different main machines and different sample feeding systems

Rapid test speed

Topsizer Plus excellent and fast dispersion system provides a good premise for the rapid testing, which enables the conventional testing to be completed in 10 seconds, greatly improves the efficiency of testing, and better meets the needs of users.

High sensitivity

Up to 103 photoelectric detection channels, dual light sources and forward, lateral, large angle and backward photodetectors constitute a three-dimensional non-blind area detection system with a maximum detection angle of 140 degrees. Before each test, the software automatically detects the signal-to-noise, which makes the instrument extremely sensitive to the small changes of the size of particles.

Good adaptation

The dispersing system with strong dispersing ability can be selected, even for super-high density metal powder and glass powder, which has good dispersing effect without precipitation, so as to meet the needs of particle size measurement with different densities to the greatest extent.

Categories

News

Contact Us

Contact: Shenzhen Kaise Technology Co., Ltd.

Tel/whatsapp: +86-15817481353

Skype: steven.yu123

E-mail: steven.yu@kaise.com

Add: Rm5061 ,Hai Wai Zhuang Shi tower ,Huafu Rd,Futian district ,shenzhen .China 518000