Battery test equipment

Tap density teste

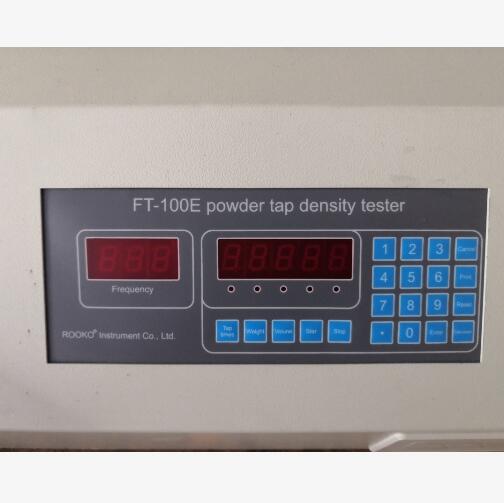

FT-100E series powder bulk density meter

I. Overview:

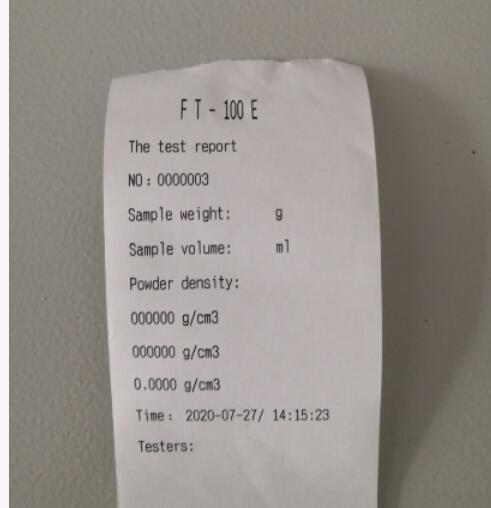

Frequency and vibration frequency are digitally displayed and can be adjusted; equipped with automatic calculation function and printer system, with password setting function, storage function, average calculation function, can print out the test time (year, month, day, hour, minute, second), mass, volume, and vibration Data functions such as actual density value, average value and test number; both vibration times and vibration time measurement modes are available; through the fixed volume combined measuring cylinder to test the loose density, the Hausner ratio and compressibility data can be obtained

2. Scope of application:

It is suitable for powder and particle research institutes, colleges and universities, and manufacturing enterprises to analyze the properties of powder and particles, and to control the cost.

3. Reference standards:

USP,BPwithEPPharmacopoeia requirements, GB/T5162-2006/ISO3953:1993; GB/T31057.2-2018

Four, parameter details

Function item | Parameter details | ||

1. Test number of stations (optional) | 1 piece | 2 pcs | 3 |

2. Test data processing method

| With printing, automatic calculation, average calculation, digital display of vibration frequency and vibration frequency

| ||

3. Use of measuring cylinder (glass material) quality method | 25ml, 100ml (optional 10ml graduated cylinder for testing samples below 25ml). | ||

4. Amplitude | Integer 1-14mm; | ||

5. Measurement mode | Zhenji | ||

6. Density | 0-9.9999g/cm3 | ||

7. Vibration frequency | 0~300 times/min Digital display | ||

8. Vibration time | 0-9999s digital display | ||

9. Reference standards

| USP,BPwithEPPharmacopoeia specifications;GB/T5162-2006/ISO3953:1993; GB/T31057.2-2018 | ||

10. Test method | Quality method (standard configuration); Volume method (purchase stainless steel combined measuring cylinder parts) | ||

11. Volumetric measuring cylinder (optional) | Equipped with stainless steel measuring cylinder 25ml; 100ml; (optional 10ml measuring cylinder for testing under 25ml). The combined measuring cylinder consists of an upper sleeve and a calibration volume measuring cylinder. | ||

12. Choice of test method | The mass method is suitable for: powder samples that are not easy to stick to the measuring cylinder; the volume method is suitable for: ultra-fine powder samples that are easy to stick to the measuring cylinder. | ||

13. Measuring cylinder requirements | 1. The volume isVolume 25±0.5ml tolerance is ±0.25ml; 2. VolumeVolume 100±1.0ml, the tolerance is ±0.5ml; 3. VolumeVolume 10±0.2ml, tolerance is ±0.10ml Equipped with a measuring cylinder cover to prevent the powder from splashing and overflowing during the tapping process. | ||

14. Repeatability | Error: ≤1% | ||

15.Accuracy | Error: ≤1% | ||

16. Liquidity Index | Compression; HausnabyHausner ratio:Tap density/loose density to obtain; need to purchase loose density meter to obtain data. | ||

17. Application Note | Pharmaceuticals, food, chemicals, batteries, abrasives, scientific research institutes, universities and colleges, corporate research and development, quality control, etc. | ||

18. Power | communicate withAC 220V(50Hz/60Hz), 40W | ||

19. Use environment | humidityLess than 85%, no condensation, no smoke, no source of mechanical vibration or electromagnetic interference | ||

20. Shop for other items

| a. 3Q verification document b. Soundproof box c. External communication weighing balance d. Moisture meter e. Powder true density meter f. Loose density meter | ||

5. Measuring cylinder and sample gauge for tap density test

It is recommended to choose a graduated cylinder with a volume of 10ml when the sample volume is less than 25ml

Volume of measuring cylinder (combined measuring cylinder)/ml | Test sample mass/g | Sample loose density/(g/cm3) |

25 | 100.0±0.5 | >4 |

50.0±0.2 | 2--4 | |

20.0±0.1 | 1--2 | |

100 | 100.0±0.5 | 1--2 |

50.0±0.2 | <1 |

6. Selection table of vibration times of some powder samples

Sample type | Vibration times/time |

Coffee powder | 300 |

Pharmaceutical powder | 500 |

Milk powder | 625 |

Industrial particles (cement, alumina powder, etc.) | 1000 |

Metal powder | 3000 |

Note: When there are other requirements, the supply and demand parties shall negotiate. | |

Comprehensive powder analysis solution:

FT-3400 powder flow behavior analyzer (static mechanics, shear method)

FT-7100 powder flow tester (dynamic mechanics, rotating drum method or rotating cylinder method)

FT-3900 powder yield strength analyzer (uniaxial compression method)

FT-3500 powder compression strength tester (compressibility, compression equation)

FT-2000 particle and powder characteristic analyzer series (traditional method)

FT-301 series powder resistivity test system (electrical performance)

ROOKO Rui Ke Instrument-Focus on powder & new material measurement and analysis instrument solutions

----Solve powder characterization: flow and no flow analysis; particle size; moisture; volume analysis; electrical conductivity, electrostatic charge analysis.

----We have been doing: R&D, production, sales, leasing, laboratory sample analysis and extension services.

Categories

News

Contact Us

Contact: Shenzhen Kaise Technology Co., Ltd.

Tel/whatsapp: +86-15817481353

Skype: steven.yu123

E-mail: steven.yu@kaise.com

Add: Rm5061 ,Hai Wai Zhuang Shi tower ,Huafu Rd,Futian district ,shenzhen .China 518000